Compact Track Loader Rubber Tracks | CTL Rubber Track Sales

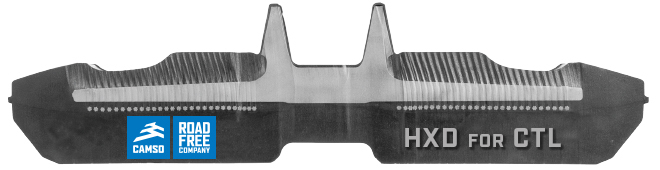

Tracks and Tires offers Free Shipping in the Contiguous 48 states. Original Equipment Manufacturer (OEM) quality Rubber Compact Track Loader Tracks available from Bridgetsone, Camso (formerly Camoplast Solideal), and MWE. Built with continuous steel cords and non-recycled rubber, these tracks are specifically designed to handle any application thrown your way.

Tracks and Tires offers Free Shipping in the Contiguous 48 states. Original Equipment Manufacturer (OEM) quality Rubber Compact Track Loader Tracks available from Bridgetsone, Camso (formerly Camoplast Solideal), and MWE. Built with continuous steel cords and non-recycled rubber, these tracks are specifically designed to handle any application thrown your way.

We also stock rubber tracks for CAT and ASV machines for a fraction of the cost from what you would pay at a dealer for OEM tracks. These high quality rubber tracks provide a long service life, excellent traction and peak handling for even the most unthinkable jobsites.

Below you will find the many available tread patterns designed specifically for your rubber track machine. Should you desire more information about our rubber tracks, give us a call and speak to one of our many professional sales reps at 877-336-6825.

Search Popular Manufacturers For Compact Track Loader Rubber Tracks

At tracksandtires.com we dominate the industry as a aftermarket and OEM rubber track supplier with 14 locations in the U.S. and Canada our rubber tracks ship directly to you. Below is a short list of our most popular compact construction equipment manufacturers we supply for.

Don’t See Your Manufacturer Listed?

Don’t Worry! We Have Tracks and Undercarriage For Thousands of Different Makes and Models.

Call To Speak With One of Our Product Specialist Today

1-877-336-6825